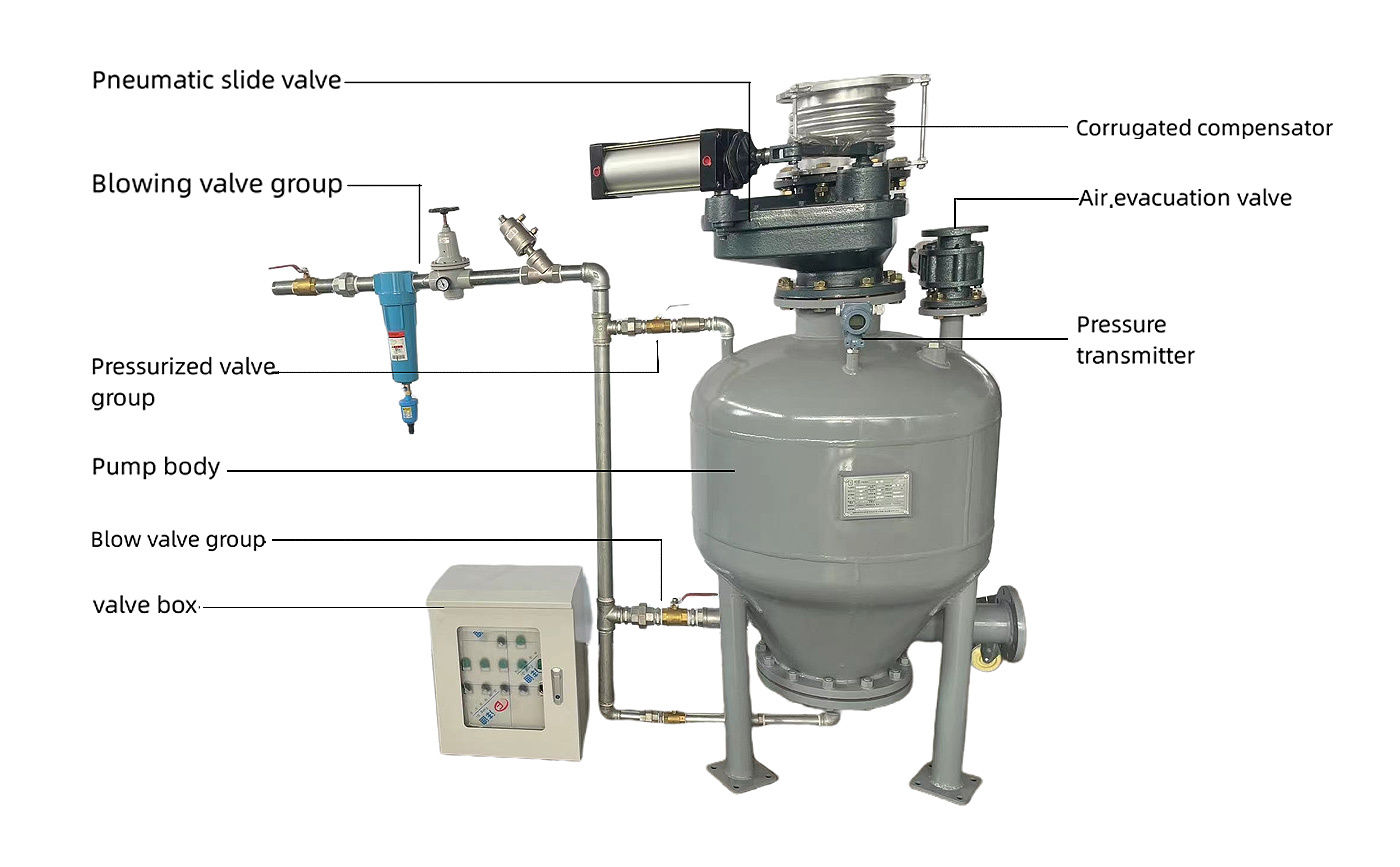

Pneumatic conveyor

Introduce

Working principle

The working process of Conveyor pump is divided into four stages:

1. Feeding stage: the feed valve and exhaust valve are opened,and the material falls into the pump body freely. When the material is full, the level meter sends a signaland the feed valve and exhaust valve are closed automatically to complete the feeding process;

2.Fluidization and pressurization stage: open the inlet valve, the compressed air flows into the upper part and the bottom of the pump body,the upper part pressurizes, the lower part diffuses and passes through the fluidized bed to make the material in fluidization state,and the pressure in the pump rises at the same time;

3. Conveying stage: when the pressure inside the pump reaches a certain value, the pressure gauge or pressure switch will send out a signal, the discharge valve will open automatically, the fluidization of the material on the fluidized bed will be strengthened, and the material in the pump will be gradually reduced when the conveying starts,at this time, the material on the fluidized bed will always be in the state of conveying while fluidizing;

4.Purging stage: when the material delivery in the pump is completed and the pressure drops to the pipe resistance, the pressure gauge or pressure switch sends out a signal, the ventilation lasts for a certain period of time, the compressed air cleans the pipeline, and then the inlet valve is closed. At a certain interval of time, the outlet valve is closed and the feed valve is opened to complete a conveying cycle.

Structure

Feature

|

---Using compressed air as the main energy source ---Solve the layering problem of powders and particles ---Made of non-toxic and corrosion resistant materials ---Non leaking capsules to prevent cross contamination ---Intelligent control and high automation |

---Material not adhering to the inner surface of the conveyor ---Modular structure, easy to clean and disassemble ---Low noise, no vibration ---Energy saving, low operating costs. |

Advantage

|

ADVANTAGE 1.Dense phase fly ash handling systems are more suitable for powder handling than mechanical conveyors because the conveying channels used in pneumatic conveyors are completely closed. |

|

|

|

ADVANTAGE 2.Dense phase fly ash treatment systems are used for material handling and transportation in various industries. Unlike many mechanical conveyor designs, pneumatic conveyors can be designed to move products between floors and around difficult angles. |

|

ADVANTAGE 3.Dense phase pneumatic conveying system is specially suitable for long-distance sealed transportation of various dust; Adaptive conveying distance is equivalent to 50-500 meters, conveying materials: fly ash, lime powder, cement, aluminum powder, mineral powder, sawdust, straw, etc. The equipment is simple and covers a small area, making full use of space. The flexible layout of pipelines makes the plant equipment configuration more reasonable. Complete system configuration, complete PLC control of the entire system, fully automated operation, and convenient maintenance |

|

MAIN PRODUCTS

CONTACT US

ADD : Zhangqiu District ,Jjinan City, Shandong Province

E-mail : candra@sdyinge.com

TEL : +86 18853147775

PROVIDE YOU WITH FREE SOLUTIONS