Rotary valve

Introduce

Working principle

Airlock valve, also named discharge valve, star discharge valve, cinder valve, is an important equipment for conveying system and dust removal system.

It is mainly used to discharge the material continuously from the tripper and dust collector, and make sure the inner pressure not exposed to atmosphere pressure environment.

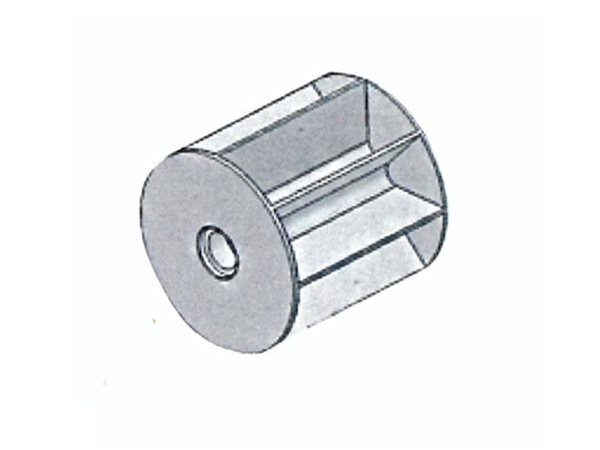

The airlock valve is made up of gear motor, sealing element, impellers and rotor housing on which many rotating blades are set. It is capable of discharging powder, small particles, flaky or fibre continuously by the differential pressure of material. Now it has been widely used in chemical, pharmacy, drying, grains, cement, environmental protection and power industry etc.

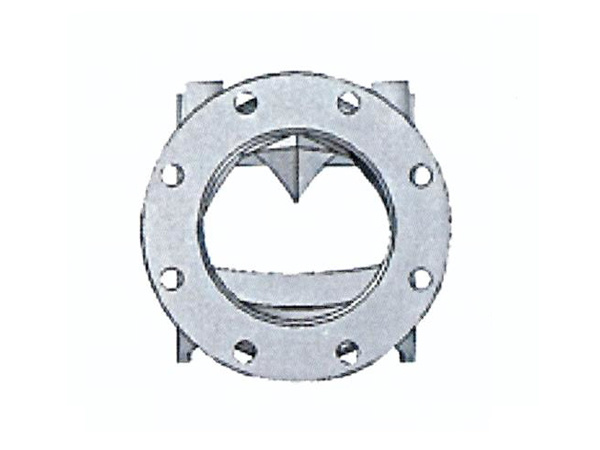

Shape of rotor:

Blades made of"人"-shaped,generally used for granular materials,effectively reduce the rotor and the shell card data.

|

|

|

|

| P(Open) | PS(Close) | V(Open) | VS(Close) |

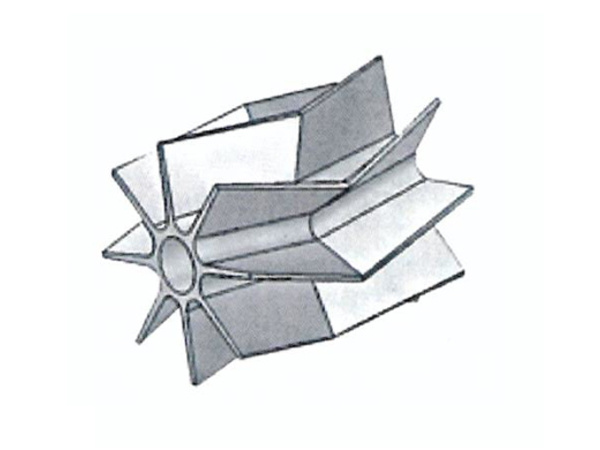

Inlet type:

|

|

| Standard type | Type W |

Note:The specific shape of the rotor and inlet type needs to be selected according to the material char acteristics and the using condition.

Structure

Feature

1. Feeding rate can be controled by adjusting the rotary speed of the impellers. Feed rate is propotional to the rotary

2. Can be used for feeding and discharging of high temperature material.

3. Certain airtightness,suitable for material discharging under differential pressure.

4. Simple structure,easy maintenance.

5. Now it has been widely used in chemical, pharmacy, drying, grains, cement, environmental protection and power industry etc.

|

|

|

MAIN PRODUCTS

CONTACT US

ADD : Zhangqiu District ,Jjinan City, Shandong Province

E-mail : candra@sdyinge.com

TEL : +86 18853147775

PROVIDE YOU WITH FREE SOLUTIONS