Four principles of pneumatic conveying system design

Time:

Mar 15,2023

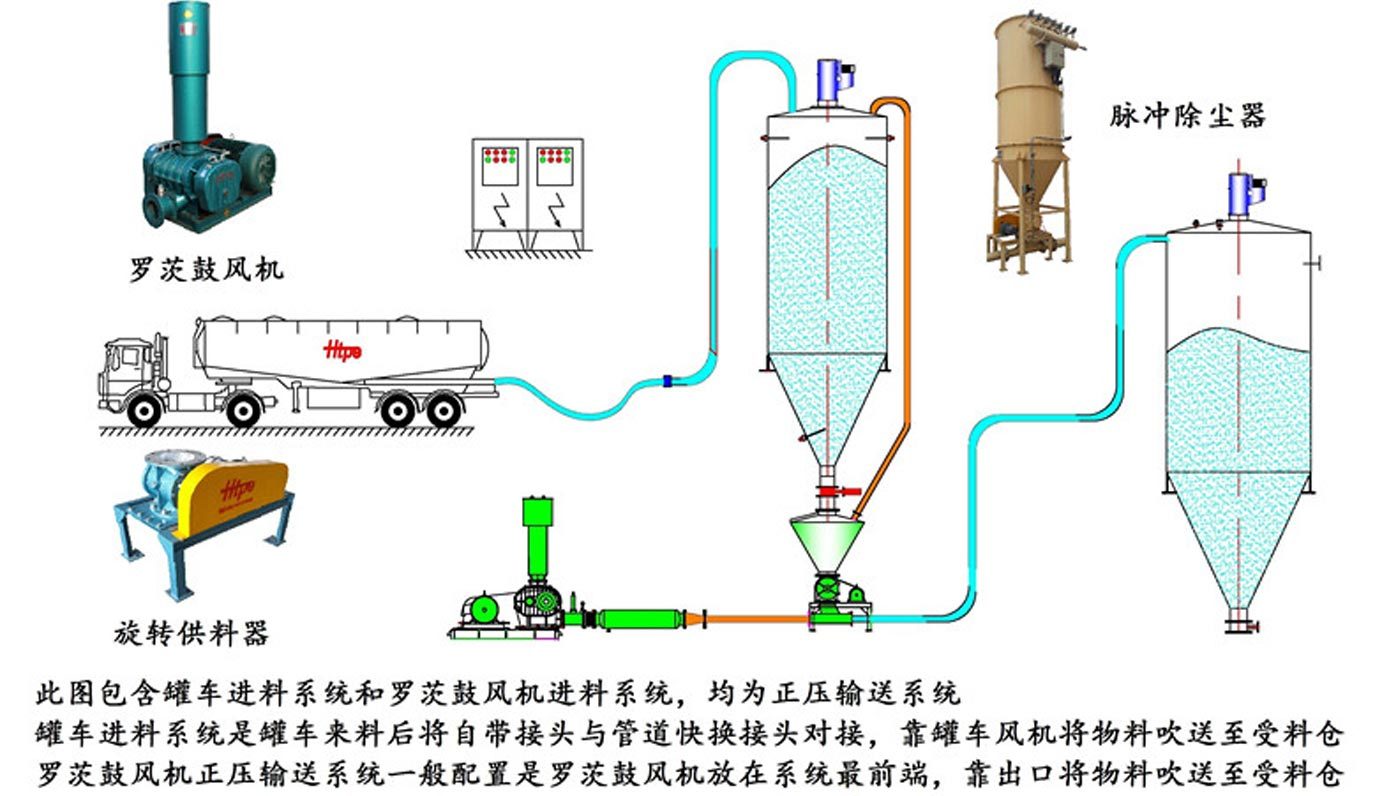

Four principles for the design of pneumatic conveying system: after calculating or distinguishing the type of material flow, dilute or dense phase pneumatic conveying facilities can be roughly selected, and then the design is done according to the following methods and steps:

1. In addition to the general requirements introduced in the previous section, the following points should be mainly considered relative to the facility design:

(1) For the facilities between the internal processes in the factory, it is necessary to pay attention to the connection between the front and rear processes, and select the material input and output form of the system;

(2) It is necessary to pay attention to the characteristics of materials and process standards, as well as the impact based on pneumatic conveying;

(3) Attention should be paid to environmental protection, mainly tail gas treatment and noise treatment. Pneumatic conveying design

2. After selecting the model of the system that arranges the transportation facilities, the layout of the system can be done well. During the layout, the location of the feeder or suction nozzle at the starting point and the location of the end separator can be established according to the facility layout of the plant, followed by the location of the air compressor and auxiliary facilities, and then the configuration of air pipes and delivery pipes, the number of pipe fittings and elbows, etc. At this time, the components, structure, performance, etc. of the system have been roughly understood. Therefore, after the layout is completed, the construction drawing design can be started.

Four principles of pneumatic conveying system design

Pneumatic conveying case

When arranging pipelines, attention should be paid to reducing the number of elbows, and in long-distance transportation, attention should be paid to making each section of horizontal pipe not too long. The pipes passing indoors and outdoors shall be well insulated, so as not to cause condensation and material sticking on the inner wall of the pipe due to temperature difference. Do not install pipe fittings that hinder the transportation on the material delivery pipe.

3. Establish the type and structure of core components to establish the type and structure of core components. Generally, the suction type mainly selects suction nozzles and separators, and the pressure type mainly selects feeders and separators. Barrel pneumatic conveying facilities mainly establish transceivers, and exchange stations should be established for round-trip conveying facilities. Establishing the form, procedure and route of automatic control is extremely important for all pneumatic conveying facilities, and sometimes even critical

4. Roughly calculate the energy required by the device system. When calculating the facility system, it is mainly necessary to calculate its required energy first, so as to roughly establish the compressor machinery. The energy required by the system is the product of air volume and pressure. The air volume can be calculated through the selection of main parameters. Therefore, the main task of the rough calculation is to roughly calculate the pressure loss of the facility system.

5. The accurate calculation of each data of the facility system is general, and the rough calculation is a kind of rough and simple calculation method when establishing the facility system scheme. Therefore, when the scheme is established, it is necessary to make accurate calculation one by one, so as to finally establish all the dimensions of the system.

Relevant News

MAIN PRODUCTS

CONTACT US

ADD : Zhangqiu District ,Jjinan City, Shandong Province

E-mail : candra@sdyinge.com

TEL : +86 18853147775

PROVIDE YOU WITH FREE SOLUTIONS